Thermoplastic Parts . thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. They are molten when heated and harden.

from www.newayprecision.com

aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. They are molten when heated and harden. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through.

What Are The Manufacturing Methods For Custom Thermoplastic Parts?

Thermoplastic Parts thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. They are molten when heated and harden. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through.

From ctech-llc.com

Reinforced Thermoplastics CTechLLC Thermoplastic Parts These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. . Thermoplastic Parts.

From www.newayprecision.com

What Are The Manufacturing Methods For Custom Thermoplastic Parts? Thermoplastic Parts aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. They are molten when heated and harden. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic —. Thermoplastic Parts.

From www.scientific.net

Thermo Mechanical Modeling of Selective Inhibition Sintered Thermoplastic Parts thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. thermoplastic — plastic material that is pliable above. Thermoplastic Parts.

From www.makepartsfast.com

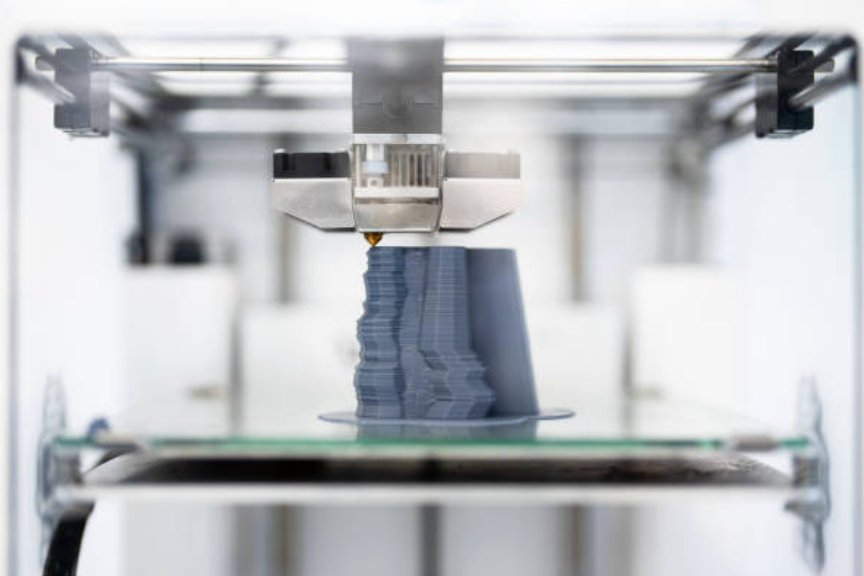

New highperformance thermoplastics drive 3D printed tools and parts Thermoplastic Parts thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic. Thermoplastic Parts.

From msicarolina.com

What Is Thermoplastic Molding? Manufacturing Services, Inc. Thermoplastic Parts thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. They are molten when heated and harden. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic —. Thermoplastic Parts.

From www.unionseal.com

Peek Polymer Plastic Molded Parts Thermoplastic Chemical And Thermoplastic Parts thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them. Thermoplastic Parts.

From www.youtube.com

preparation and uses of thermoplastics part 1 YouTube Thermoplastic Parts thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. These polymers can be melted, molded, and reshaped. Thermoplastic Parts.

From www.google.com

Patent US20110111172 Compression Molding Method and Reinforced Thermoplastic Parts aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing. Thermoplastic Parts.

From www.slideshare.net

Thermoplastic Technologies, Delhi, Filter Casings & Part Thermoplastic Parts thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres. Thermoplastic Parts.

From www.newayprecision.com

What Are The Manufacturing Methods For Custom Thermoplastic Parts? Thermoplastic Parts thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. They are molten when heated and harden. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. . Thermoplastic Parts.

From www.researchgate.net

(PDF) Silver Streaks on Surface of Injected Thermoplastic Parts Thermoplastic Parts thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. They. Thermoplastic Parts.

From kimw.shop

Guide to surface defects on thermoplastic injectionmoulded parts Thermoplastic Parts thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. They are molten when heated and harden. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. thermoplastic materials. Thermoplastic Parts.

From acereare.en.made-in-china.com

MCCB Thermoplastic Parts 250A Handle Black China MCCB and Metal Stamping Thermoplastic Parts thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. They are molten when heated and harden. thermoplastic materials are a type of polymer that. Thermoplastic Parts.

From acereare.en.made-in-china.com

MCCB Thermoplastic Parts M1400 Handle China MCCB and Metal Stamping Thermoplastic Parts aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them apart from their thermosetting counterparts. . Thermoplastic Parts.

From www.inyopools.com

Hayward Commercial Thermoplastic SelfPriming Pump HCP Series Parts Thermoplastic Parts thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. They are molten when heated and harden. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. These. Thermoplastic Parts.

From www.inyopools.com

Waterco Thermoplastic Series Top Mount Parts Thermoplastic Parts thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. They are molten when heated and harden. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. These polymers can be melted, molded, and reshaped multiple times without significant chemical changes, setting them. Thermoplastic Parts.

From www.google.ca

Patent EP0569928A1 Online consolidation of filament wound Thermoplastic Parts aerospace components, reinforcing fibres, high temperature resistance foams, chemical fibres and arc welding torches. thermoplastic — plastic material that is pliable above certain temperatures, capable of being molded. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing. Thermoplastic Parts.

From wagnervandam.com

Ebook Material Selection For Thermoplastic Parts Practical And Advanced Thermoplastic Parts They are molten when heated and harden. thermoplastic materials are a type of polymer that becomes soft and moldable when heated, allowing them to be shaped into various forms. thermoplastics are defined as polymers that can be melted and recast almost indefinitely. thermoplastic polymers are amorphous or semicrystalline polymers constituted of large macromolecules associated through. These polymers. Thermoplastic Parts.